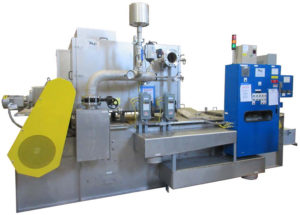

Vacuum Filters

Contaminated liquid is fed into the filter via a low velocity inlet distributor. As air is drawn from beneath the filter media bed, a pressure differential across the media is created. The contaminants are extracted by the filter media and form a cake. As the formed cake becomes thicker and less permeable, a liquid pool is formed in the filter bed. Over time, a vacuum switch signals the media drive to index the media and introduce fresh media into the entrance of the filter bed. Contaminants and spent media are discharged out the other end of the filter bed. A vacuum breaker pipe assembly is supplied to reduce the vacuum stress put on the belt during initial indexing, thus prolonging the life of the belt. During the indexing of the media, flow from the filter is uninterrupted.

The clean liquid entering the vacuum chamber gravity flows through the clean fluid outlet into a separate clean tank for delivery back to the process, or directly to the process tank, depending on design. The discharged contaminants are exposed to the drying action of the extraction chamber, which pulls additional liquid from the cake and returns the liquid to the system, minimizing liquid make-up requirements. The result is drier contaminants, which makes disposal more convenient and less costly.