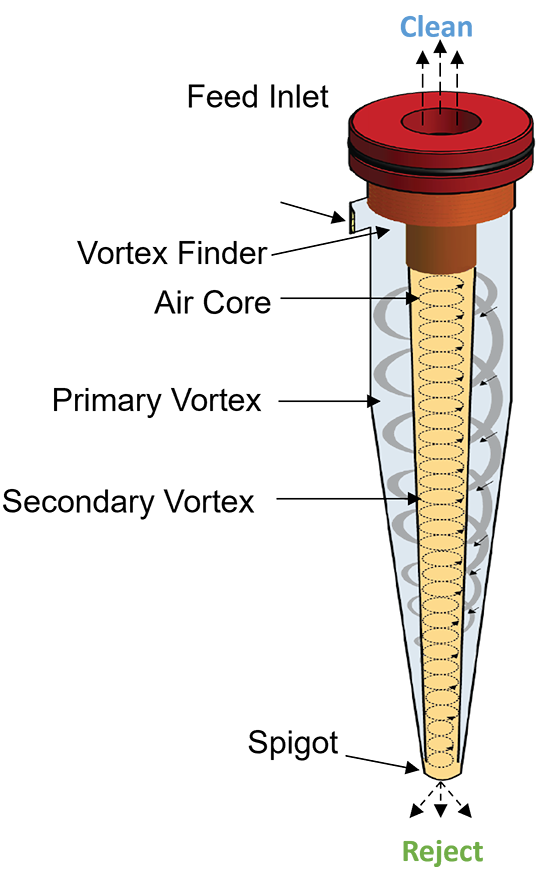

How Hydrocyclones Work

Process solution enters the Liquid Cyclone through a tangential Feed Inlet, having a downward slope. Accelerated by centrifugal action, the process solution spirals downward through the Vortex Finder along the wall contour toward the small end of the cone. The undesirable heavy particles such as grit, weld balls, dirt, metal, etc., are forced by the Primary Vortex to the outer wall and carried down and out the Spigot of the cone. The cleaned solution spirals up the Air Cor center via the Secondary Vortex and exits out the Vortex Finder at the top of the cleaner.

In Automatic ALSI HDC Series Cyclones, the contaminants collect in a stilling chamber where the reject materials are separated from the solution and the rejects settle into a collection vessel at the bottom. A knife gate valve separates the stilling chamber and the collection vessel. The ALSI HDC Series purges the rejects through a timed control of two reject valves.

The manual liquid cyclone is emptied once or twice each shift by manually closing the reject collection vessel isolation valve, depressurizing the collection vessel, and opening the rejects collection valve. With both the manual and automatic system, there is almost no process solution loss and both are extremely difficult to plug.